Transparency & Traceability

The ALDI SOUTH Group works closely with business partners to increase transparency and traceability in supply chains. We want to understand the origins of the products we sell and the raw materials we use - and support our customers in making more informed purchasing decisions.

Why is traceability so important?

Global supply chains can be highly complex. The more parties involved (e.g. suppliers, subcontractors, producers, workers, communities), the harder it is to maintain a high level of traceability. Without the knowledge of where our products come from and how they are produced and sourced, we cannot ensure compliance with our requirements.

Therefore, supply chain traceability is the foundation for all our sustainability measures and responsible sourcing practices. It helps us analyse risks, implement and monitor projects, and improve the quality of our products.

Our goals:

Our ALDI production partners and facilities

We attach great importance to sustainable production and manufacturing conditions for our products. Our business and production partners play a key role in implementing ALDI’s social and environmental standards across all supply chain activities. To be transparent with our customers and stakeholders, we are publishing the names and addresses of our suppliers for the selected food and non-food supply chains*. We are also an official contributor to the Open Supply Hub (OSH).

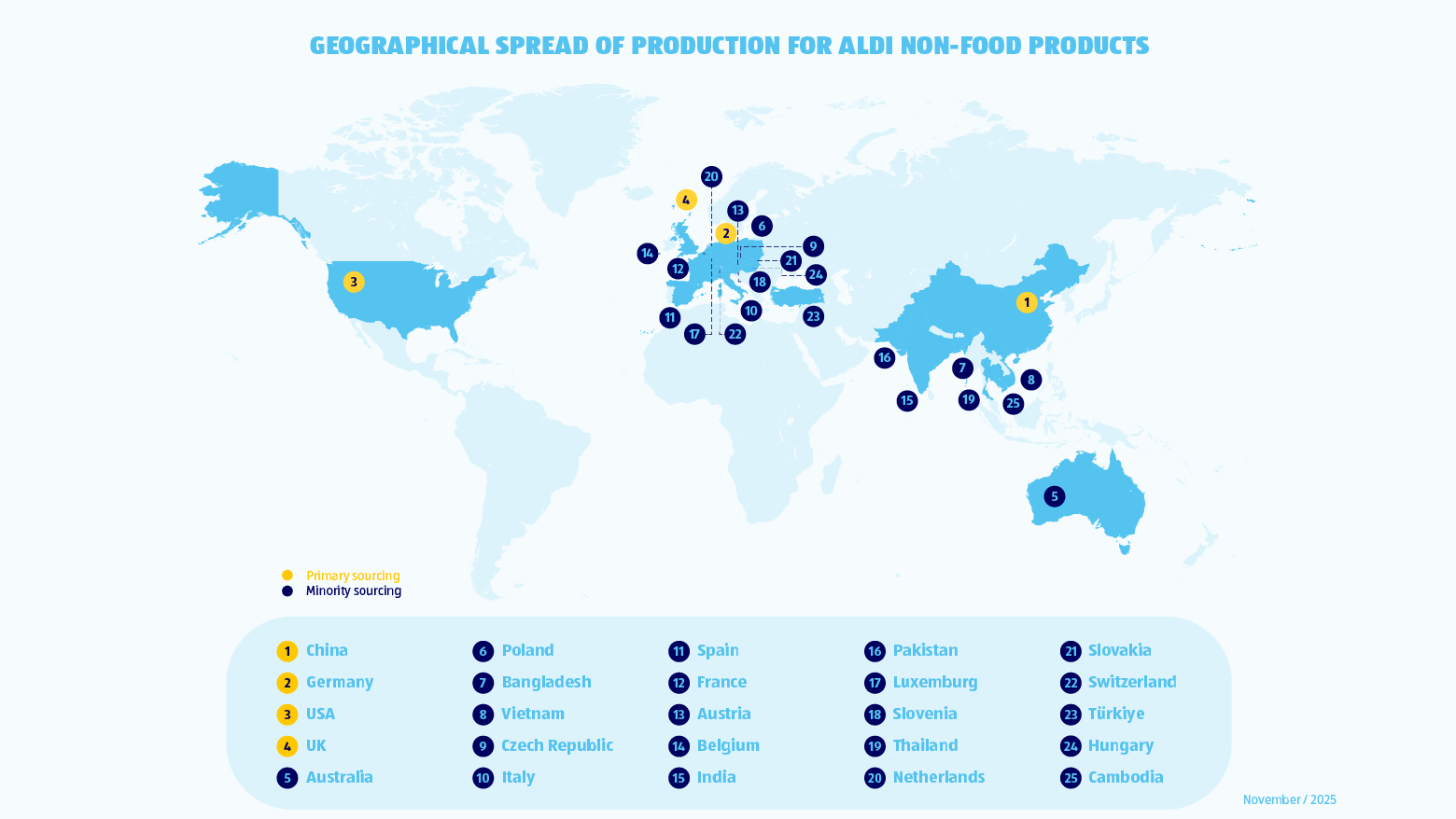

This overview represents the countries of final production facilities for ALDI Non-Food products based on 2025 Buying Volume, with a breakdown of primary and minority sourcing.

All countries with minimal Buying Volume (< 0.5%) are excluded from this overview.

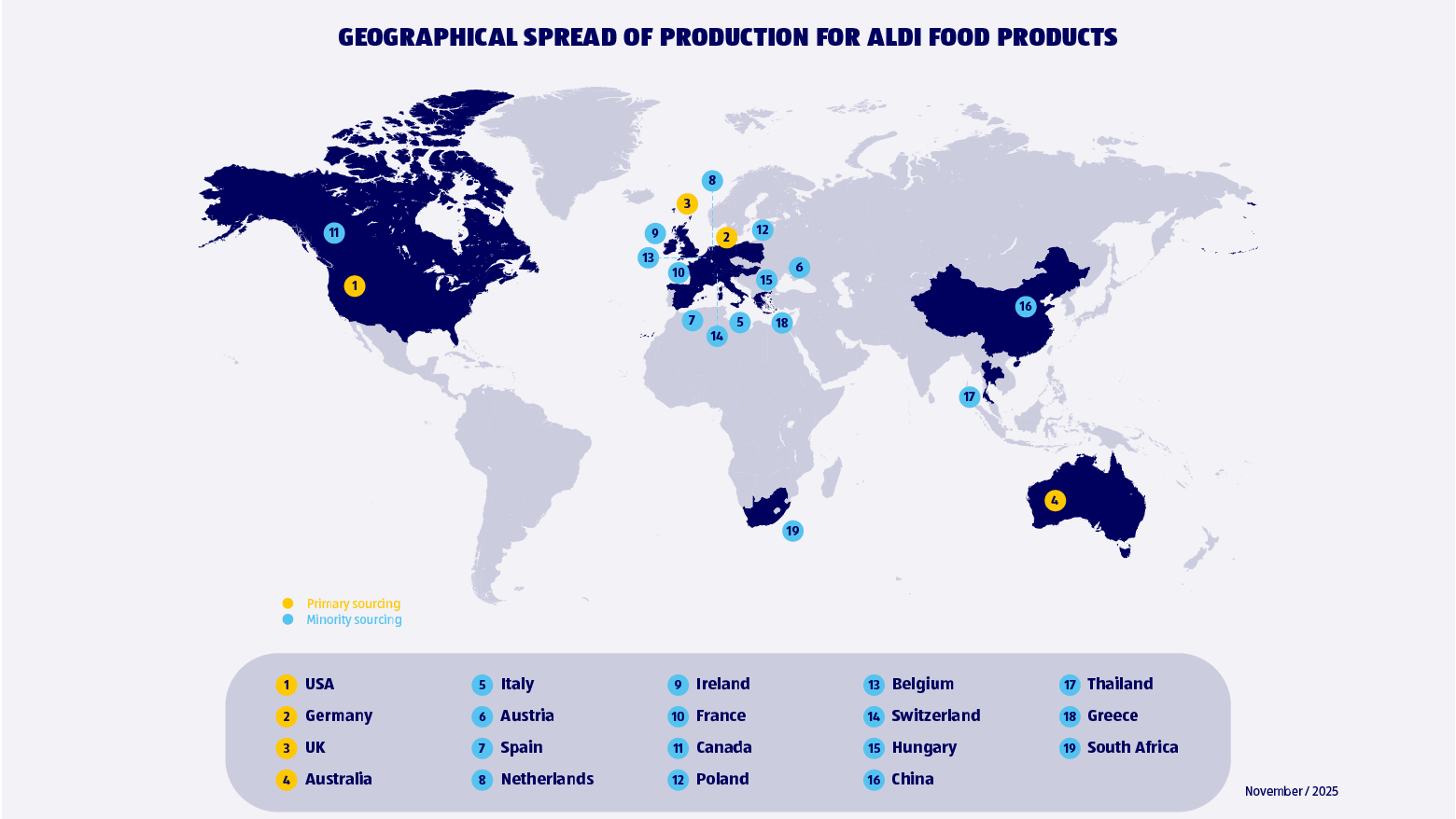

This overview represents the countries of final production facilities for ALDI Processed Food products as well as growers countries for ALDI Fresh Produce products based on 2025 Buying Volume, with a breakdown of primary and minority sourcing.

All countries with minimal Buying Volume (<0.5%) are excluded from this overview.

ALDI’s Choceur CHOCO CHANGER bars are made of 100% responsibly sourced cocoa. We joined Tony’s Open Chain and adopted its 5 Sourcing Principles, one of them being traceability.

Tony’s BeanTracker traces the cocoa beans at any point in the supply chain. We can see where the beans are grown and the amount of cocoa every cooperative and farmer has supplied before being shipped and processed in Belgium. This also allows us to keep track of the social circumstances and ensure that the farmers earn a living income and receive their premiums.

ALDI’s Choceur CHOCO CHANGER bars are made of 100% responsibly sourced cocoa. We joined Tony’s Open Chain and adopted its 5 Sourcing Principles, one of them being traceability.

Tony’s BeanTracker traces the cocoa beans at any point in the supply chain. We can see where the beans are grown and the amount of cocoa every cooperative and farmer has supplied before being shipped and processed in Belgium. This also allows us to keep track of the social circumstances and ensure that the farmers earn a living income and receive their premiums.

Transparency for our products

While traceability is important for us as a company to conduct human rights and environmental due diligence in our supply chains, it also allows our ALDI customers to make better-informed purchasing decisions. Knowing where the products come from, how they were processed, and whether they are ethically and sustainably sourced allows them to choose responsibly. Today’s customers demand more in-depth product information. The ALDI SOUTH Group aims to meet this expectation by disclosing our suppliers and partners and making supply chain activities transparent and visible.

The “Check your product” platform by HOFER Austria, HOFER Slovenia, ALDI Hungary and ALDI Suisse has been established to offer customers more transparency on fish, meat, and soy products. ALDI SÜD Germany uses the ALDI Transparency Code (ATC) platform to offer transparency specifically for fish, meat and eggs. By scanning a QR code or inserting the tracking number on the packaging, the products can be traced back to their origins.

Source: *The Food Industry Association